What is Additive Manufacturing (AM) or 3D Printing?

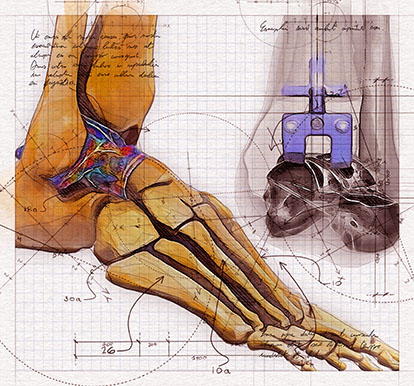

Medical three-dimensional (3D) printing, which is based on Additive Manufacturing (AM), is an emerging area of technology that explores how 3D printing can be used to replace or support an existing biological structure, create Patient Specific Implants/Instruments (PSI), replicate the unique and often complex topography of each individual patient’s deformity, and allow for the surgeon to “rehearse” a correction on a computer before they execute the plan on a patient during surgery.

Medical three-dimensional (3D) printing, which is based on Additive Manufacturing (AM), is an emerging area of technology that explores how 3D printing can be used to replace or support an existing biological structure, create Patient Specific Implants/Instruments (PSI), replicate the unique and often complex topography of each individual patient’s deformity, and allow for the surgeon to “rehearse” a correction on a computer before they execute the plan on a patient during surgery.

3D printing based technologies represent a shift in the medical manufacturing industry that is a direct result of recent advancements in the Additive Manufacturing industry which has led to improvements in both the size and affordability of 3D printers. This has set the stage to make this customized technology widely accessible, allowing doctors and researchers to create personalized devices and solutions for patients.

A related area of 3D printing called bioprinting, involves combining structural printing and the biological printing of human tissue and organs by layering living cells instead of pure plastic or titanium. While bioprinting remains in the experimental phase, the ability to print human tissue will likely have a huge impact on such things as the design of personalized medications, organ or tissue transplants, surgical operations, and complex reconstructive surgery. In Europe, for example, scientists have figured out how to print a “living skin” to transfer directly onto patients who have suffered full thickness skin loss or extensive burns.

The Rise of Medical 3D “Makerspaces”

While 3D printing was first invented by Charles Hull in the late 1980’s, it didn’t start to become mainstream until last several years. At first, it was typically utilized by hobbyists who sought to print out novel items such as a toy, a miniaturized copy of their dog, or a plastic replacement part for their car. These hobbyists would then share their concept or solution online with each other. This was called a “makerspace” and served as an open forum to new and exciting creations. We then saw a few medical device solutions, such as finger splints, customized shoe insoles, and braces make their way into these makerspaces. More recently we have begun to see several medical device companies create their own “medical makerspace” and are now becoming the key drivers of the 3D printed medical market. Three such examples are Materialize, 4Web, and Additive Orthopaedics.

Furthermore, some medical practitioners have now begun using on-site 3D printers to produce medical devices right in their offices. The dental field has paved the way for this with temporary caps, crowns, and Invisalign. Current examples of medical 3D printing successes include the creation of specialized customized orthotics, custom casts and limb prosthetics, as well as custom implant solutions in the dental industry that are 3D printed on-site.

Furthermore, some medical practitioners have now begun using on-site 3D printers to produce medical devices right in their offices. The dental field has paved the way for this with temporary caps, crowns, and Invisalign. Current examples of medical 3D printing successes include the creation of specialized customized orthotics, custom casts and limb prosthetics, as well as custom implant solutions in the dental industry that are 3D printed on-site.

Dr. Adam Perler works closely with several of the existing 3D printing makerspaces and has been recognized as one of the leading centers in the country when it comes to incorporating customized patient specific surgery, PSI and 3D printing. Dr. Adam Perler and Alexander Orthopaedic Associates are also currently laying down the groundwork to create our very own medical 3D printing makerspace and be one of the first offices in the country to do so.